EPG Companies' patented SurePump™ Leachate Pumps provide superior performance and accurate liquid level reading for horizontal side slope riser and vertical sump applications.

The SurePump is a completely sealed unit, built with stainless steel to withstand harsh environments and equipped with superior E-Glide™ bearings*. To maximize cooling, unlike competitor models, the SurePump draws leachate over the motor, assuring years of trouble-free performance. In addition, the level sensor is mounted along the central axis of the sump drainer assuring an accurate leachate level reading no matter how the pump is installed.

Horizontal models incorporate four or five wheels on each end of the pump, depending on the size, to help facilitate easy installation and correct positioning during operation.

Innovative patented design, long-lasting performance and accurate “central-axis” level sensing are reasons EPG’s SurePump is the leachate pump of choice among 1,000’s of landfill professionals.

Models are available in a wide range of flow rates, discharge heads, and motor voltages.

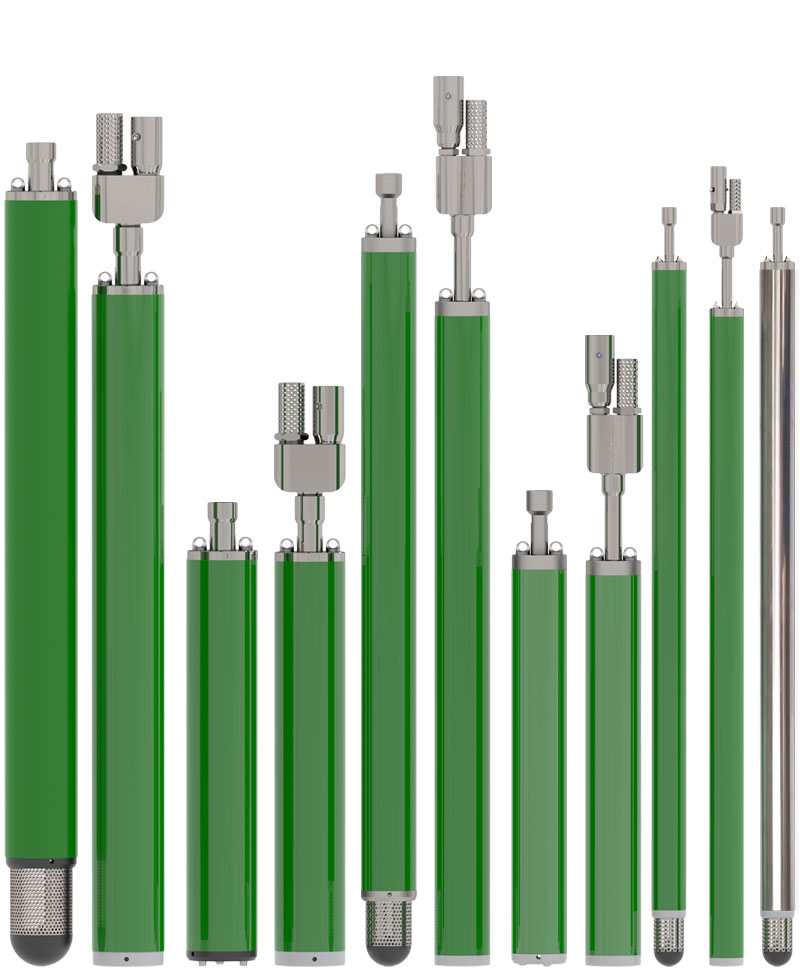

Standard SurePumps™ configurations include:

- WSDPT: Wheeled Sump Drainer with integral level sensor for side slope riser applications

- WSD: Wheeled Sump Drainer for side slope riser applications

- VSDPT: Vertical Sump Drainer with integral level sensor side mounted

- VSDCPT: Vertical Sump Drainer with integral level sensor center mounted

- VSD: Vertical Sump Drainer

- TSP: Submersible Pump

| Series | Flow Range | Nominal Flow |

|---|---|---|

| Series - 2 | 1-14 GPM | 10 GPM |

| Series - 3 | 10-20 GPM | 15 GPM |

| Series - 5 | 15-30 GPM | 25 GPM |

| Series - 7 | 20-50 GPM | 35 GPM |

| Series - 9 | 20-50 GPM | 45 GPM |

| Series - 11 | 35-80 GPM | 62 GPM |

| Series - 14 | 45-95 GPM | 77 GPM |

| Series - 18 | 20-120 GPM | 85 GPM |

| Series - 31 | 50-200 GPM | 150 GPM |

| Series - 47 | 75-300 GPM | 230 GPM |

| Series - 61 | 50-400 GPM | 300 GPM |

| Series - 77 | 75-500 GPM | 385 GPM |

| Series - 95 | 95-680 GPM | 475 GPM |

| Series - 125 | 125-850 GPM | 625 GPM |

| Component | Standard | 316 Stainless Steel |

|---|---|---|

| Check Valve Housing | 304 Stainless Steel | Special Order |

| Check Valve | 304 Stainless Steel | Special Order |

| Check Valve Seat | E-Glide™ | Special Order |

| Diffuser Chamber | 304 Stainless Steel | Special Order |

| Impeller Seal Ring | E-Glide™ | Special Order |

| Impeller | 304 Stainless Steel | Special Order |

| Motor Adapter | 304 Stainless Steel | Special Order |

| Inlet Screen | 304 Stainless Steel | Special Order |

| Pump Shaft | 304/431 Stainless Steel | Special Order |

| Coupling | 329/420/431 Stainless Steel | Special Order |

| Fasteners | 304 Stainless Steel | Special Order |

| Bearings | E-Glide™ | Special Order |

| Component | 1/3 to 2 Horsepower Pollution Recovery | 3 to 60 Horsepower Sandfighter |

|---|---|---|

| End Bell Castings | 304 Stainless Steel over Iron | 304 Stainless Steel over Iron |

| Stator Shell | 301 Stainless Steel | 301 Stainless Steel |

| Shaft Extension | 303 Stainless Steel | 303 Stainless Steel |

| Fasteners | 316 Stainless Steel | 300 Stainless Steel |

| Seal Cover | Tefzel | Sintered Bronze |

| Shaft Seal | Viton | Viton, Carbon, Ceramic Face Seal |

| Diaphragm | Viton | Nitrile Rubber |

| Diaphragm Plate | 304 Stainless Steel | 304 Stainless Steel |

| Diaphragm Spring | 302 Stainless Steel | 302 Stainless Steel |

| Diaphragm Cover | 316 Stainless Steel | 304 Stainless Steel |

| Slinger | Viton | Nitrile Rubber |

| Lead Sleeve | 316 Stainless Steel | 316 Stainless Steel |

| Lead Jam Nut | 316 Stainless Steel | N/A |

| Lead Jam Clamp | N/A | N/A |

| Lead Potting | Epoxy | Epoxy |

| Lead Bushing | Viton | Viton |

| CP Cable | SBR Rubber | SO Neoprene | PVC | |

|---|---|---|---|---|

| Unaged Physicals | ||||

| Tensil Strength (psi) | 2500 | 1420 | 1630 | 1410 |

| 100% Modulus (psi) | 340 | 690 | 770 | 780 |

| Elongation (%) | 650 | 300 | 300 | 330 |

| Low Temperature Properties | ||||

| Brittle Point (°F) | < -100 | -52 | -38 | -32 |

| Cold Bend @ -35°C | Pass | Pass | Pass | Pass |

| Cold Bend @-50°C | Pass | Pass | Fail | Fail |

| Cold Bend @-65°C | Pass | Fail | Fail | Fail |

| Aging Properties | ||||

| - Air Oven 7 days @ 121°C | ||||

| % Retention of Tensile | 107 | 104 | 188 | 124 |

| % Retention of Elongation | 115 | 17 | 17 | 0 |

| - Air Oven 7 days @ 136°C | ||||

| % Retention of Tensile | 97 | 0 | 0 | 0 |

| % Retention of Elongation | 90 | 0 | 0 | 0 |

| - Air Bomb 42 hrs @ 127°C | ||||

| % Retention of Tensile | 88 | 56 | 93 | 97 |

| % Retention of Elongation | 113 | 18 | 43 | 83 |

| - Oxygen Bomb 7 days @ 80°C | ||||

| % Retention of Tensile | 98 | 118 | N/A | 109 |

| % Retention of Elongation | 93 | 87 | N/A | 94 |

| Ozone Resistance | ||||

| Hours to Cracking | ||||

| (100 pphm/100°F) | >1000 | 24 | N/A | >1000 |

| Heat Deformation (T2/T1) | ||||

| 2000 gms @ 121°C | .86 | .93 | .95 | .70 |

| Mechanical Properties | ||||

| Crushing Strength | ||||

| - lbs force to failure | 3400 | 2000 | N/A | 3000 |

| Abrasion Resistance (Uniroyal) | ||||

| - cycles to wear thru jacket | 36 | 18 | 14 | 43(1) |

| (1) Material Coated Abrasive Wheel | ||||

| Chemical Resistance | ||||

| Water Resistance | E | G | G | E |

| Acid Resistance | E | G | G | G |

| Alkali Resistance | E | G | G | G |

| Aliphatic Resistance (gasoline, kerosene) | E | A | A | G |

| Aromatic Hydrocarbons (benzol, toluol) | E | A | A | A |

| Oil | E | A | A | E |

| Legend: E = Excellent G = Good A = Average | ||||

| Ratings based on average performance of general purpose compounds. | ||||

** Teflon is a registered trademark of DuPont.

The SurePump Wheeled Sump Drainer is protected by U. S. patent #4,966,534 and #4,992,030. Additional patents pending.

Leachate Pumps

Leachate Pumps