The EPG Flow Controller (FCSA) System provides batch volume control of liquids. This system operates by keying in the amount of desired liquid to be pumped. The controller will count up to the input amount and then stop a pump or close a valve.

The user friendly system features a microprocessor based digital display meter and requires a 115 Volt, 60 Hertz, single phase power supply (standard). The front panel is menu driven to provide easy set up and calibration. The flow meter retains full function in temperatures between 32° and 131° F. In lower temperature applications, the monitoring system can be equipped with a thermostatically controlled panel heater that helps eliminate condensation, optimize meter accuracy, and extend the life of the system.

- UL/CUL listed

- Digital LCD display

- Factory tested

- Non-volatile memory

- Field programmable

- Available in several sizes and configurations to fit most applications

- Available with optional intrinsically safe (IS) barrier for use in classified, hazardous atmospheres

- Easy set up via front panel keypad for maximum gallons per day or truck load

For more liquid level and flow measuring and control components, see:

VERSATILITY

The FCSA Flow Controller has the flexibility to work with a variety of flow sensors.

Examples:

Paddlewheel: Flowing liquid turns a paddlewheel, which sends out a pulse proportionate to flow rate. It can be used with pipe sizes from 1" to 14" with flow rates of 2 to 1,850 gpm.

Magnetic: The magnetic sensor measures flow by passing the liquid through a magnetic field and measuring the voltage produced. Since the induced voltage is proportional to the average flow velocity and the inside diameter of the pipe is known, the volumetric flow rate can be calculated. It can be used with any pipe size.

Ultrasonic: This sensor is attached to the outside of the pipe. It operates by transmitting a high frequency signal off of solids entrained in the liquid and reading the return signal. The detected frequency shift is proportional to the liquid velocity (Doppler Effect). It can be used with any pipe size.

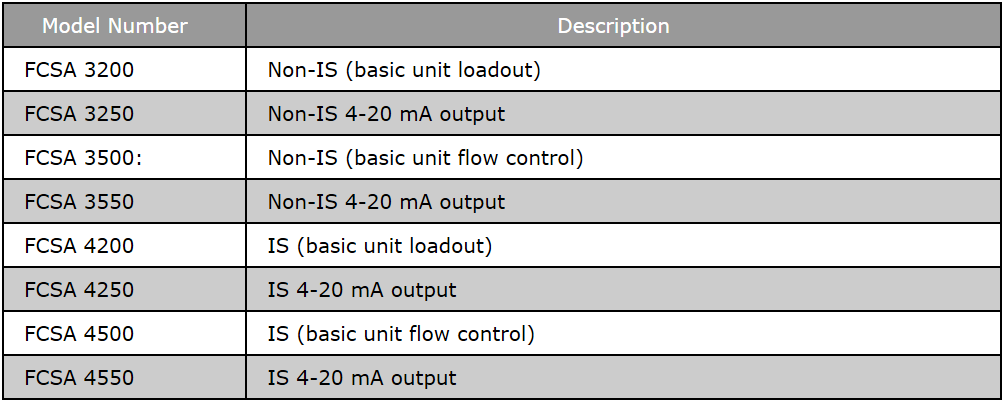

The system is available in two configurations:

FCSA 3200 & FCSA 4200

- Used for truck loadout with manual reset

FCSA 3500 & FCSA 4500

- Used for limiting GPD to your permitted amount with automatic reset and 24 hour timer

- Options include ticket printer, remote control and remote data collection

Flow Controller – FCSA

Flow Controller – FCSA