Essentials for Side Slope Riser Applications

EPG Companies Inc. has provided landfill pumping systems and pollution control equipment for over 35 years. Through our years of design, engineering and manufacturing expertise, field knowledge, and extensive partnering with thousands of professionals in the landfill industry, we have provided safe, cost-effective solutions that are now being recognized as essential system components for achieving optimum landfill operation. In side slope riser applications, we recommend the use of the following time-tested, field-proven EPG components.

Downloads

Main Components

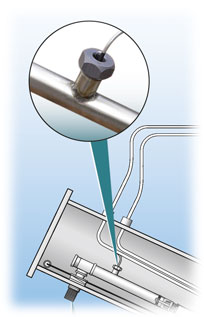

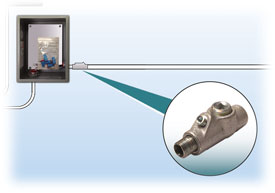

One of the essential components to safe landfill operation are EPG Breakout Junction Boxes. When installed between your riser, well or sump and control panel, they offer benefits that might otherwise be overlooked. Running your motor and sensor cable to the control panel can be expensive and dangerous! The moisture and possibly explosive, corrosive gases that migrate through the conduit can cause control panel failure and expensive repairs. If you want to increase the safety and accuracy of your system, install an EPG Breakout Junction Box with a gas-tight seal off fitting. This will eliminate migration of harmful gas and will help simplify maintenance and/or repair work by creating a new, easy to access connect/ disconnect location.

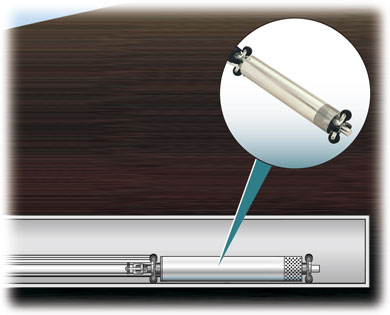

EPG’s Liquid Flow Sensor uses a patented special axle and dual magnet drum pickup to create an accurate, low cost, repeatable, flow sensor.

- *Hand tighten

- *Easy to clean

- *Simple to install

- *Easy to replace

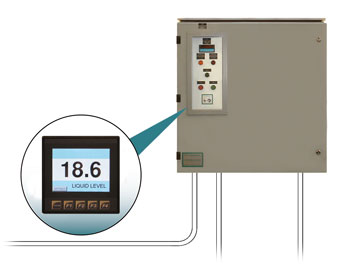

Uncompromising control . . . that's what you get with an EPG, UL & CUL/CSA listed control panel! Whether you need a simple controller or a custom integrated system, all EPG Control Panels are designed and built by electrical and process engineers; seasoned professionals who understand the overall operational requirements of even the most complex systems.

In addition to our custom designed panels, EPG manufactures a broad line of standard controllers that can be equipped with a vast array of options required to meet your specific application. Our OCS unit (right) offers level & flow monitoring and more in one device. Each EPG Control Panel is tested as a complete system and then delivered installation-ready, helping to reduce integration problems and start-up costs and providing years of maintenance-free process system control.

(Note: We strongly recommend controller be mounted a minimum of 3 feet above grade and a minimum of 15 feet from riser.)

Installing a Gas Seal-Off Fitting* between the breakout junction box and control panel keeps your control panel free from harmful migrating moisture and potentially explosive, corrosive gases.

* Can be used with any EPG Breakout Box model.

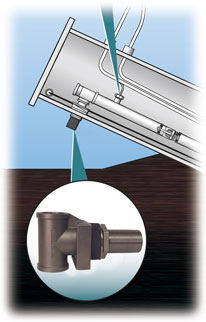

EPG’s Disconnect Adapters are designed to fasten through a riser or sump wall allowing personnel to easily and safely make pump connections and/or disconnections without entering hazardous locations. Many sizes and configurations are available.

EPG’s patented SurePump Wheeled Sump Drainers provide superior performance and accurate liquid level reading for horizontal side slope riser applications. The SurePump is completely sealed, built of stainless steel for harsh environments and, unlike competitor models, draws liquid over or past the motor to maximize cooling and extend the life of the pump. At least four wheels are in contact with the riser pipe at all times and the patented, easy-to-remove submersible level sensor is mounted along the central axis of the sump drainer to assure an accurate level reading no matter how the pump is positioned. Models are available in a wide range of flow rates, discharge heads, and motor voltages.

Horizontal Pump Design Guide

Horizontal Pump Design Guide